Views: 0 Author: Natasha Publish Time: 2026-01-06 Origin: Cugle

If you're new to starting enamel pin projects, you may be wondering about the quality of lapel pins and how to evaluate different manufacturers. Since enamel pins involve multiple handcrafted production processes, it can be difficult to judge whether a pin manufacturer is truly reliable. Many buyers assume enamel pins are a standardized product. In reality, quality can vary dramatically from factory to factory. Enamel pins can be beautifully made, durable and long-lasting, but only when they are produced using the right materials, processes and standards. Unfortunately, not every factory is willing to execute every step to that level.

That's why choosing the right supplier is essential.

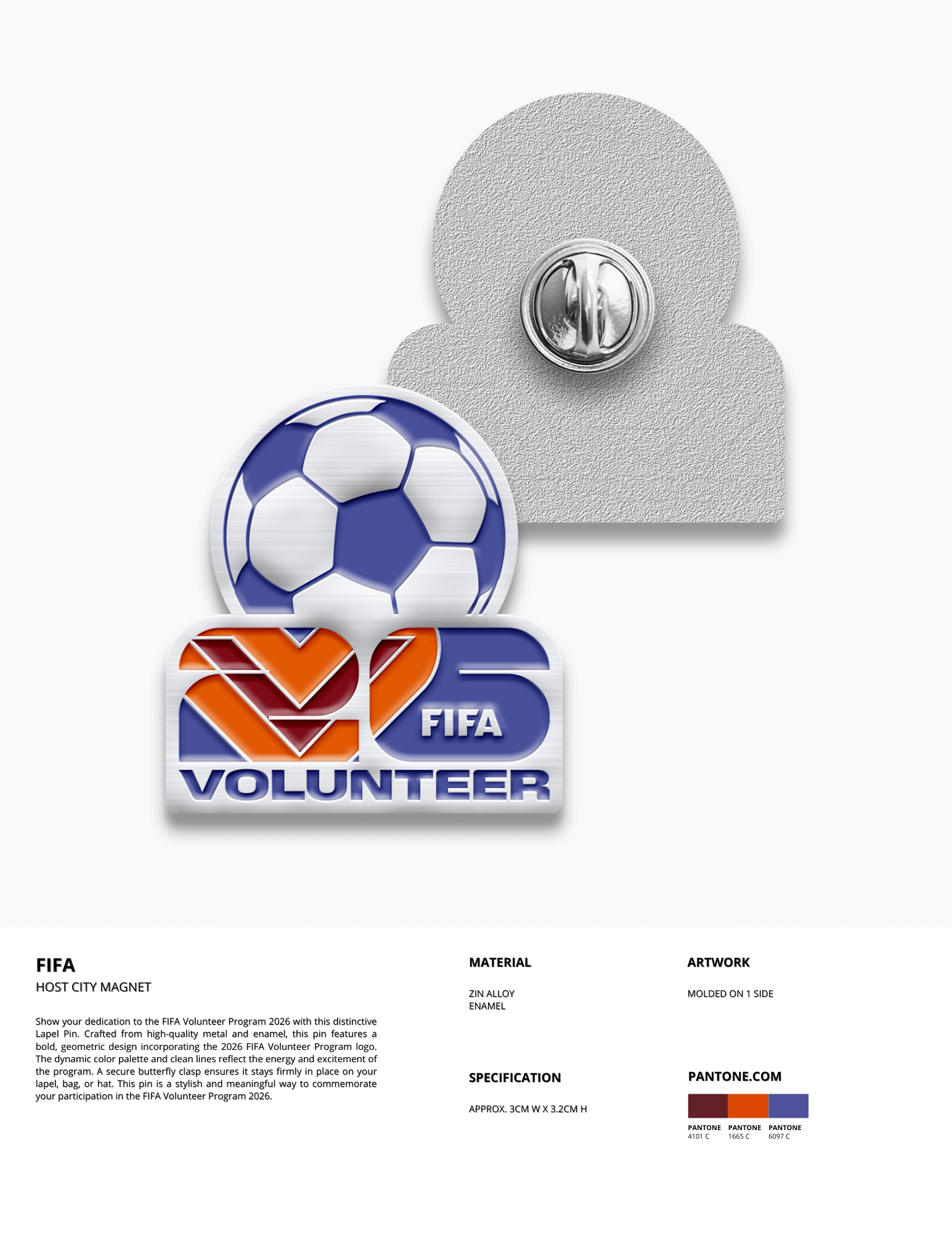

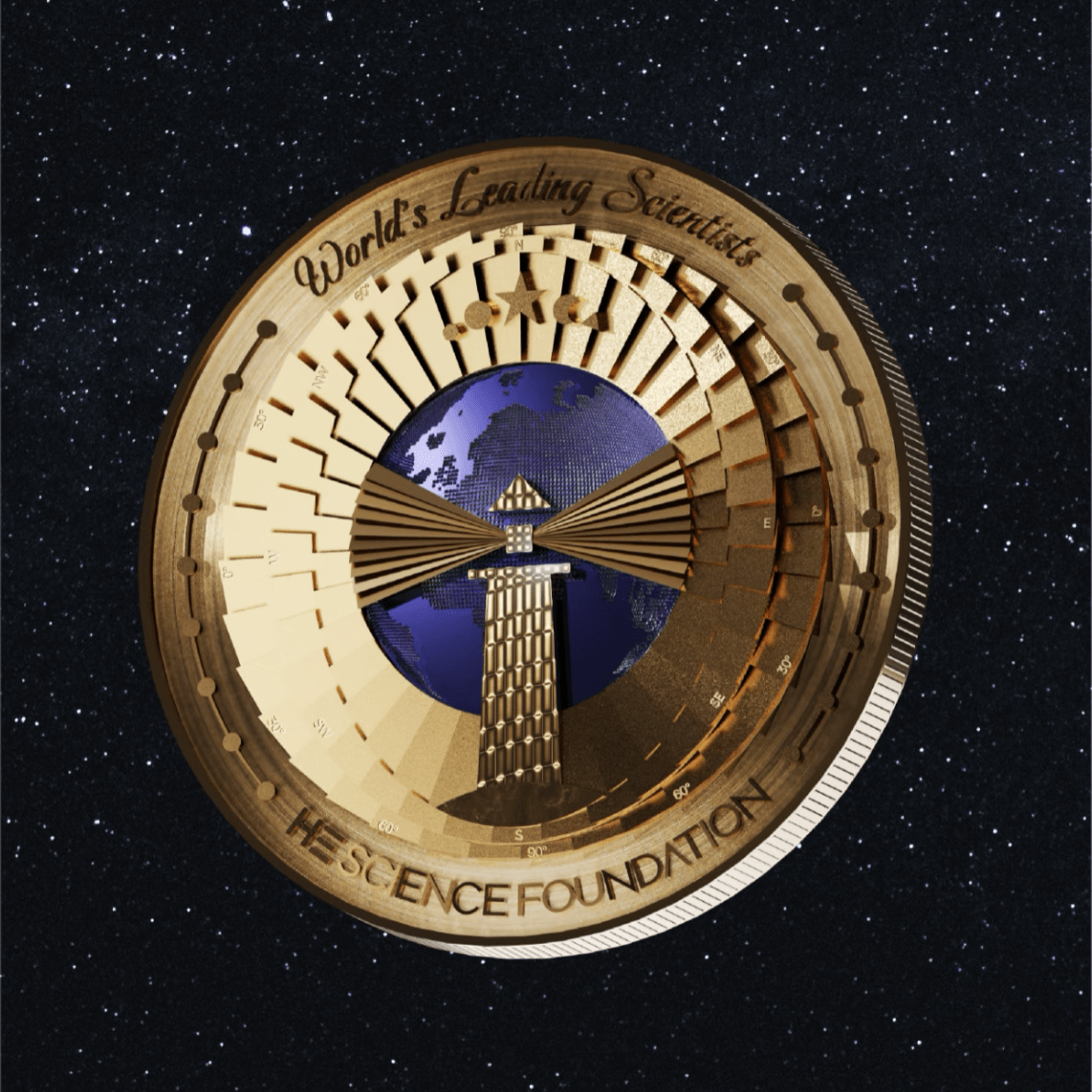

As a supplier to global brands such as Disney and FIFA, Cugle regularly visits and studies craftsmanship workshops and electroplating facilities. Based on this hands-on experience, we can confidently say that quality differences between factories can be dramatic, even when the designs look similar at first glance.

If you select a manufacturer at random on platforms like Etsy, Amazon or Alibaba without a basic understanding of how enamel pins are made and the standards for them, there is a real risk you may regret the decision and waste both time and money.

Let's take a closer look at the key factors that define a truly high-quality enamel pin manufacturer, and how the right partner can turn your "pinspiration" into reality.

Cheap enamel pins don't fail by accident. They fail because quality is compromised at multiple stages of production.

The difference between a high-quality factory and a low-quality one usually comes down to:

Material selection |

Manufacturing discipline |

Time spent on each process |

Quality control standards |

Willingness to reject flawed pins |

These choices define whether a pin becomes a long-lasting accessory or a short-lived disappointment.

High-quality enamel pins start with solid metal bases such as iron, brass and reliable zinc alloy that maintain their shape over time. Cheap factories often use thinner or inconsistent metal to reduce cost, resulting in pins that bend easily or feel flimsy.

We select metal base such as iron, brass and zinc alloy based on durability and intended use (not minimum cost), which ensures each pin feels substantial and stable in hand.

In addition to metal bases, enamel paints play a critical role in producing high-quality enamel pins. Low-cost factories often use inferior enamel paints, which can result in dull colors, poor adhesion and enamel that chips or flakes off over time.

We use high-quality enamel paints selected for both durability and finish. Our production relies on premium enameling brands, valuing smooth flow, long-lasting performance, a high-gloss finish and clean, well-defined edges.

Uneven enamel, dust, bubbles, and sunken colors are common failures in cheap enamel pins. These flaws usually come from rushed filling and shortened curing cycles.

We carefully control enamel filling and curing times, allowing colors to fully set and stabilize. This is also why we typically request a 14-day production lead time from our clients. It’s not because we are "slow", but because we invest the necessary time in every handcrafted custom pin to bring out the highest level of precision and finish in each piece.

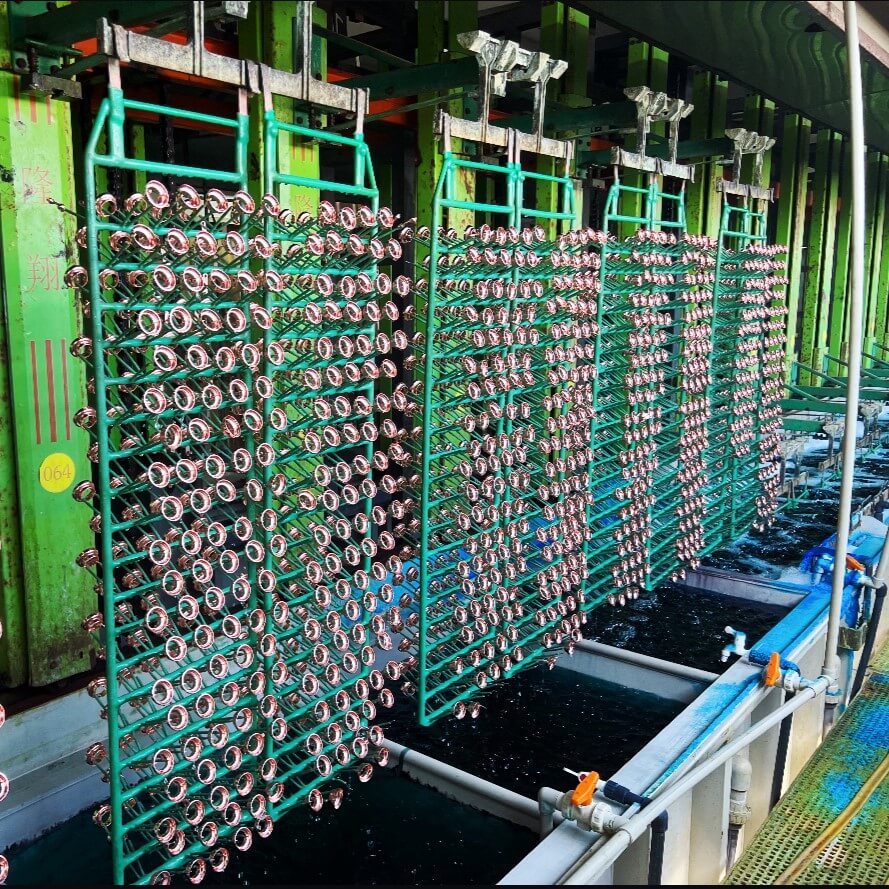

Thin or low-grade plating may look acceptable at first, but it wears off quickly, exposing base metal, discoloring edges and shortening the pin's lifespan.

In compliance with China's environmental protection regulations, electroplating factories are required to operate within designated industrial parks equipped with advanced pollution treatment systems. We partner exclusively with electroplating facilities that demonstrate a strong commitment to environmental responsibility while maintaining the technical capability to apply consistent, durable plating finishes.

These finishes are engineered for real-world wear, not just showroom appeal. While this approach does increase our production costs, we remain committed to responsible manufacturing and to protecting the environment we all share.

A pin that falls off is a failed pin, no matter how nice it looks.

Many low-cost pins use weak posts or loose clutches to save fractions of a cost.

We prioritize secure post alignment and reliable backing options, reducing the risk of loss and improving everyday usability.

The is the single biggest difference between high-quality pins and cheap ones. Low-cost production often accepts a higher defect rate to protect margins. Pins with scratches, uneven fills or plating flaws are still shipped.

Only A-grade pins are allowed to leave our factory and reach our customers. Each pin is carefully inspected to ensure there are no visible air bubbles, no under-filled enamel even in small or hard-to-notice areas, no dust or debris trapped in the enamel or glitter, and no flaws in the electroplating finish. All colors must be clean, accurate and precisely in place.

Cheap promotional enamel pins don't fail randomly. They fail for very specific reasons rooted in how they are made.

They often fail because:

1. Materials are downgraded, sacrificing strength and durability for lower costs

2. Processes are rushed, leaving little room for precision or correction

3. Defects are tolerated, as long as the product looks acceptable at a glance

4. Long-term wear isn't considered, only short-term appearance. A standard electroplating finish should be able to stay for 2 years.

These shortcuts may reduce upfront costs and increase efficiency, but they inevitably lead to pins that bend, fade, chip or fall apart over time.

High-quality enamel pins, on the other hand, succeed because of a fundamentally different mindset:

1. Every step is intentional, from material selection to final inspection

2. Standards are enforced, not adjusted to meet price targets

3. Longevity matters because the pin is meant to be worn, kept and remembered

The difference isn't the design and the proof, it is the discipline behind it. It's the willingness to slow down, reject flawed pieces and prioritize craftsmanship over convenience.

The answer is "Yes", enamel pins can be excellent in quality. But quality is not guaranteed by the product type alone. It is the result of deliberate choices made at the factory level.

When craftsmanship, materials and quality control are treated as non-negotiable, enamel pins don't just look good on day one, they continue to look good in at least 2 years later.

As a lapel pin buyer, one important step before choosing a high-quality manufacturer is to ask as many questions as possible, questions relating to materials, enamel filling or electroplating, etc. Pay close attention to how quickly and how thoroughly they respond, this often reflects their level of professionalism and responsibility.

Many sellers you find on platforms such as Etsy, Amazon or Alibaba are not actual factories but middlemen. Once they receive your inquiry, they may source low-cost factories to offer attractive pricing, but they are often not directly responsible for the quality of the lapel pins produced.

That's why asking detailed questions matters. You can even request factory videos or production footage, which can be a strong indicator of what to expect once you begin a project with them.

If you're looking for a reliable, high-quality custom lapel pin manufacturer, contact us today. With 20 years of experience in metal and enamel customization, Cugle provides OEM and ODM services for top global brands. Our professional team offers free design support, ensuring every pin meets your exacting standards.