Views: 0 Author: Natasha Publish Time: 2025-10-22 Origin: Site

Believing you are filled with great excitement and ambitions to create dedicated crafts, ready to step into the amazing world of lapel pins while browsing this website, you might find yourself confused when you encounter the term 'soft enamel' and 'hard enamel'. As a pin designer, it can be difficult to visualize the real texture of the final product when comparing a soft enamel pin to a hard enamel pin based on 2D artwork. This blog aims to help simplify the decision. We will walk you through the core production process of both technological processes, compare the key differences and showcase some finished product to help you decide which craft suits you the best.

Visually, the biggest difference between soft enamel and hard enamel pin is the texture. Soft enamel pin has raised metal lines, while hard enamel pins have a smooth, flat surface, which leads to different production processes. Essentially, the starting process for both crafts is almost the same. The molding department creates a mold based on the provided artwork, and with the finished mold, the metal base of pin can be formed using the molding machine. What is important to note at this stage is that the molds differ for each craft, and a soft enamel mold can be modified into a hard enamel mold, but a hard enamel mold cannot be modified into a soft enamel mold.

At this point, the paths for the two craft products diverge, with completely different further steps emerging in the production of soft enamel pin and hard enamel pin.

When we have the metal base ready, there are four major steps in order to finish a high-quality soft enamel lapel pin.

In this step, the metal bases are seperated from the entire batch of molded products. There will be rough and irregular raised metal along the connections of the metal bases. Polishing smooths these raised edges, forming the perfect contours of a soft enamel pin.

Electroplating is a process that applies an outer layer to iron or zinc alloy. This helps slow down metal erosion and also enhances the metal base. Common electroplated colors are fake gold, nickel, copper and brass, with finishes that can be either shiny, matte or antique.

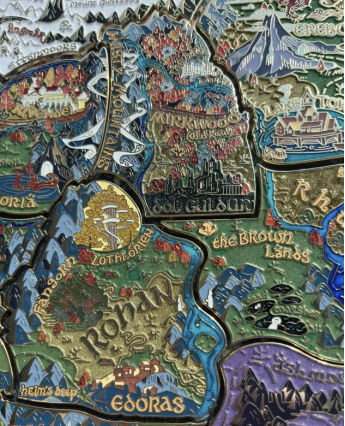

Enameling is a step which colored enamel liquid is applied to the surface of the metal, creating a strong finish. In soft enamel pins, the cavity formed by molding is not completely filled, leaving the raised edges of the pin noticeable to the touch. In this picture, the liquid enamel ia applied in varying amounts to different cavities to create a design inspired by nature.

After the colored enamel is filled, the pins are placed in an oven to bake and set the colors.

Now that we've covered the main process for soft enamel pins, let's take a look at how hard enamel pins are produced.

Unlike soft enamel pins, which use only a small amount of colored enamel, the color-filling process for hard enamel pins is much more extensive. A large amount of colored enamel is completely filled into each cavity-so much that the original design of the pin becomes unrecognizable at this stage. This step ensures that the color remains intact during the next step-polishing.

The baking process for hard enamel pins also differs from that of soft enamel pins. Hard enamel pins are baked after each color is filled. For example, if a hard enamel pin contains 10 colors, it will be baked 10 times-once after each colored enamel application.

In this part, the hard enamel pin is polished by hand until the surface becomes smooth and flat. You can still see the metal lining, but they are so even and refines that they appear to be part of the colored enamel.

By now, not only has the range of electroplated colors expanded, but the available finishes have also diversified-from the common shiny look to matte, antique and rainbow effects. You can even choose double electroplated color on one lapel pin. These electroplated options have greatly increased design possibilities, making lapel pins more beautiful and varied than ever. Choosing an electroplated color is a very important part in customizing your lapel pin.

Now that we understand the production processes for both soft enamel and hard enamel pins, it’s time to discuss how to choose the better option. Essentially, the design itself is the key factor in deciding between two crafts.

For soft enamel pins, the production process does not include surface polishing. As a result, the metal lines are thinner than those on hard enamel pins-the thinnest can be 0.12mm, with 0.15mm being more common. Below are two lapel pins with the same design but made using different techniques: the one on the left is hard enamel, and the one on the right is soft enamel. You can see that the golden mountains on the soft enamel pin stand out with sharp, vivid edges, giving it a 3D appearance, while the mountains on the hard enamel pin are flat and appear 2D. This demonstrates that choosing between soft and hard enamel largely depends on your design concept.

The polishing technique gives hard enamel pins a premium, refined, and high-end appearance. It also makes them more durable and scratch-resistant. However, the additional production steps and higher materiel costs make hard enamel pins more expensive to produce, which is why they are often the first choice of high-end brand and military.

As we've seen, soft enamel and hard enamel each have their own strengths, and both can make beautiful pins depending on the design and presenting purpose.

At Cugle, we offer end-to-end soft enamel and hard enamel craftsmanship, including artwork design, precise mold making, electroplating, enameling and thorough quality check. Backed by a skilled production team, we ensure every lapel pin meets the highest standards of quality and design.

Have a project but still unsure whether soft enamel or hard enamel is the right choice for your lapel pin? Contact Cugle's sales team today for professional guidance and a custom quote.